13 de January de 2026

Salmonella in the Food Industry: Risks, Prevention, and Control Strategies

What Is Salmonella and How Does It Affect Food Safety?

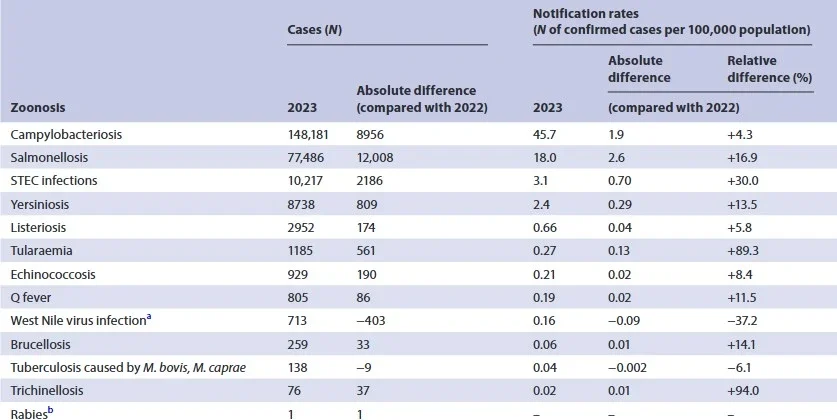

Salmonella is one of the most significant pathogens in the food industry due to its ability to contaminate a wide variety of products and cause outbreaks of foodborne illnesses. It is a genus of Gram-negative bacteria belonging to the Enterobacteriaceae family, capable of surviving in different environments and withstanding technological processes when adequate controls are not applied. The genus Salmonella includes more than 2,500 serotypes, the most common being S. Enteritidis and S. Typhimurium. These bacteria are zoonotic pathogens, meaning they can be transmitted from animals to humans through food.

Its impact on food safety lies in its ability to:

- Colonize the gastrointestinal tract of humans and animals.

- Survive on processing surfaces and equipment for long periods of time.

- Withstand environmental stress conditions such as acidity, desiccation, or low temperatures.

Food safety is highly compromised because even low infectious doses (10² to 10³ bacterial cells) are sufficient to cause illness, which makes it necessary to implement strict controls at all stages of the supply chain.

The most common symptoms of salmonellosis are diarrhoea, abdominal pain, fever, nausea, vomiting, and general malaise, and they may appear between 6 and 72 hours after consuming contaminated food.

These symptoms typically last 4 to 7 days. Complications are uncommon in healthy individuals, but special care should be taken with vulnerable populations such as children, the elderly, and immunocompromised individuals.

Salmonella in the Food Industry: Causes and Risks

The main causes of Salmonella contamination in the food industry include:- Contaminated raw materials: raw meat, eggs, unpasteurized milk, and vegetables irrigated with contaminated water.

- Contaminated water used in washing or cooling food.

- Poor hygiene practices during handling, storage, or transportation.

- Cross-contamination between raw products and ready-to-eat foods.

- Failures in the cold chain that allow bacterial growth.

- Food handlers who are carriers of the bacteria.

Salmonella Prevention in Food Production Plants

Prevention focuses on the implementation of food safety management systems such as Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP), and proper staff training: 1. Hygiene:- Routine cleaning and disinfection of equipment and surfaces.

- Use of detergents and disinfectants effective against Salmonella.

- Selection of certified suppliers.

- Regular inspections and microbiological testing.

- Ongoing training in food safety.

- Implementation of personal hygiene protocols, such as handwashing and the use of appropriate protective clothing.

- Monitoring of process water.

- Verification of air quality in critical areas.

- Physical separation between raw product areas and ready-to-eat product areas.

- Prevention of cross-flows of personnel and materials.

- Maintaining appropriate refrigeration and freezing temperatures.

- Continuous monitoring through recording systems.

Do you want more information?

We help you

In accordance with Regulation 2016/679 (GDPR) the basic information on personal data protection is provided below:

- Data controller: PROQUIMIA, S.A.

- Purpose of processing: Managing the sending of information, resolving queries and/or collecting data for possible business relationships.

- Legal Basis: Consent of the person concerned

- Recipients: No data will be transferred to third parties, unless this is legally obliged.

- Rights: Access, rectification, deletion, opposition, limitation, portability and presentation of claims.

- Additional information: Additional and detailed information on Data Protection can be found on our website: Privacy policy