7 de October de 2024

Cleaning and disinfection of milking facilities

On dairy farms, cleaning and disinfection of milking equipment and milking circuits is essential to ensure animal health, milk quality, consumer food safety and farm efficiency and profitability. Implementing and maintaining rigorous milking facility hygiene procedures not only enables compliance with stringent milk production hygiene regulations, but also contributes to the success and sustainability of the business.

Types of waste in milking facilities.

Knowledge of the characteristics of the dirt accumulated on milking equipment is essential to understand the requirements for designing appropriate cleaning protocols. Two main types of dirt accumulate in milking equipment:- Organic residues: these are mainly composed of fats, proteins and sugars from milk. It is important to remove this dirt from surfaces as soon as possible after milking because over time it dries and hardens into deposits that are difficult to remove.

- Inorganic residues: these are minerals (usually calcium, magnesium and iron) present in milk or water, which precipitate under alkaline conditions or by heat.

Cleaning and disinfection products

Several types of products are used for cleaning and disinfection of milking installations:- Alkaline detergents: dissolve organic-based deposits (fats, proteins and carbohydrates in milk). In addition, they soften and suspend other wastes, facilitating their removal through the mechanical action provided by the turbulence of recirculation.

- Alkaline-chlorinated detergents: these are alkaline detergents containing chlorine, which provides disinfectant properties and improves the removal of protein residues, allowing alkaline cleaning and disinfection in one step.

- Acid detergents (descalers): Detergents based on organic or inorganic acids or a combination of both. Its main action is to remove accumulated mineral deposits and especially milk stone.

- Disinfectants: they are used after an acid or alkaline wash phase, with the objective of leaving the facility with the appropriate hygienic levels for the next milking operation. They can also be used in pre-washed installations as an individual step prior to milking. The most commonly used disinfectant products are based on peracetic acid, a high-performance biocidal active ingredient with a broad disinfectant spectrum at low doses.

Cip cleaning equipment

Cleaning operations should be carried out according to a carefully designed procedure to achieve the required degree of cleanliness, ensuring that the sequence is exactly the same each time it is performed. Cleaning In Place (CIP) systems allow cleaning product solutions and rinse water to circulate through the circuits and equipment without the need to dismantle facility components, allowing full automation of the cleaning process, with correct adjustment and control of water temperature, cleaning product dosing and circulation times. In addition, the correct regulation of the cleaning solution flow rate, its recirculation speed and air injection allow for a turbulent flow that generates a mechanical scrubbing effect of the dirt present on the internal surfaces of the equipment.Cip cleaning and disinfection procedures for milking facilities

A CIP cleaning cycle comprises several stages. The correct combination of the alkaline cleaning, acid cleaning, disinfection and rinsing stages allows optimum cleaning and disinfection of the facilities, ensuring optimum hygienic conditions.Pre-rinse

It should always be done immediately after milking, in order to prevent milk solids from drying and sticking to the internal surfaces of the equipment, which would make removal difficult. If slightly warm water is used, the remaining milk fat is more easily removed. Rinsing with lukewarm water allows the milk residues to remain soluble, thus facilitating their removal. In addition, it prevents the pipe from cooling down, preventing it from absorbing the heat of the detergent solution in the next cleaning phase. Using water that is too hot or too cold can cause milk to stick to the internal surfaces of the milking equipment:- Water that is too hot (> 55 °C) causes the proteins to denature and form a sticky film on the surfaces.

- Water that is too cold (< 35 °C) causes grease to solidify and form a greasy film on surfaces, making it difficult to remove.

Alkaline / alkaline-chlorinated washing

Its main purpose is to remove organic dirt of fatty and protein origin from the milk. To ensure satisfactory results from the alkaline cleaning phase, the following 4 variables must be considered:- Detergent concentration: A detergent must reduce the surface tension of the cleaning solution and be able to disperse dirt and suspended particles to prevent flocculation. The detergent concentration must be adjusted according to the type of facility, considering that during the cleaning phase the solution is diluted with the rinse water and milk residues, with some neutralisation also taking place. It is therefore necessary to dose the detergent according to the manufacturer's instructions and to check that sufficient concentration is maintained throughout the cleaning phase.

- The washing solution should start its circulation at a temperature between 60 and 80 ºC and it is important that it does not fall below 40-45 ºC at the end of the phase to ensure the efficiency of the process and to prevent milk solids from re-depositing on the surfaces.

- In CIP systems, the mechanical effect is provided by the recirculation of the cleaning solution, which in combination with air, causes a turbulent flow. Pumps in the CIP system must be sized to obtain velocities to generate a turbulent flow, ensuring that a mechanical effect is created that contacts all pipe surfaces.

- Cleaning duration: should be carefully calculated to obtain the optimum cleaning effect. Normally, the wash cycle should last between 8-10 minutes depending on the size and type of facility. The detergent should circulate long enough to dissolve the dirt, but do not overdo it to prevent the water from getting too cold.

Acid washing

Depending on the hardness of the water and the number of milkings per day, an acid wash is alternated between alkaline washes. Typically, with hard water, two alkaline washes are performed for each acid wash, and with soft water, 1 to 3 acid washes are performed per week. To ensure satisfactory results from the acid cleaning phase, the 4 variables indicated in the alkaline cleaning stage must also be considered.Final rinse

After the washing phase, the surfaces must be rinsed with potable water for sufficient time to remove all traces of the cleaning solution. A good final rinse is essential to ensure that no chemical residues remain that could contaminate the milk or attack metal surfaces, leaving the milking facilities properly prepared for the next use. Finally, all parts of the system must be completely drained after flushing.Verification of cleanliness

Verification of the effectiveness of the whole process should be considered an essential part of the cleaning operations. One form of verification is by visual inspection, but because process lines are rarely accessible for visual inspection, this has been replaced by microbiological testing, focused on several critical points of the line, after the CIP programme has been completed. It is also important to remember that regular maintenance and calibration of the milking equipment is essential.Conclusions

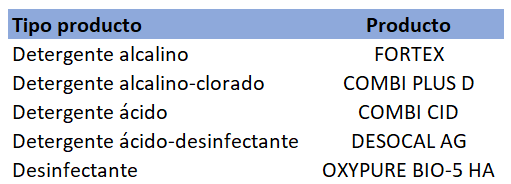

The design and implementation of cleaning and disinfection protocols for milking facilities is essential to ensure cow health, milk quality, consumer safety and dairy farm profitability. CIP cleaning and disinfection systems ensure maximum standardisation of processes, providing great time savings for dairy farmers, thus contributing to the success and sustainability of the business. PROQUIMIA, with more than 50 years of experience in the hygiene sector, provides technical support for the design and implementation of cleaning and disinfection protocols for milking facilities, advising on the selection of the most suitable detergent and disinfectant products for each facility and providing staff training in their correct use. The PROQUIMIA product range for cleaning and disinfection processes of milking facilities consists of the following products:Catalogue

- Cleaning and sanitation of dairy equipment and containers [Internet]. Neologic Engineers. [citado el 10 de abril de 2024]. Disponible en:

- Cleaning and sanitizing milking equipment [Internet]. Thedairysite.com. [citado el 10 de abril de 2024]. Disponible en:

- Cleaning of dairy equipment [Internet]. Dairy Processing Handbook. 2015 [citado el 3 de abril de 2024]. Disponible en:

- Heguy J. How to properly clean milking equipment [Internet]. Ag Proud. 2011 [citado el 10 de abril de 2024]. Disponible en:

- Limpieza y desinfección del equipo de ordeño. Identificación de problemas de limpieza (2a parte) [Internet]. Revistafrisona.com. [citado el 5 de abril de 2024]. Disponible en:

- Limpieza y desinfección del equipo de ordeño. Identificación de problemas de limpieza (1ª parte) [Internet]. Revistafrisona.com. [citado el 5 de abril de 2024]. Disponible en:

- Smith S. How to clean your milking equipment for low-risk raw milk — [Internet]. Raw Milk Institute. 2022 [citado el 3 de abril de 2024]. Disponible en:

Do you want more information?

We help you

In accordance with Regulation 2016/679 (GDPR) the basic information on personal data protection is provided below:

- Data controller: PROQUIMIA, S.A.

- Purpose of processing: Managing the sending of information, resolving queries and/or collecting data for possible business relationships.

- Legal Basis: Consent of the person concerned

- Recipients: No data will be transferred to third parties, unless this is legally obliged.

- Rights: Access, rectification, deletion, opposition, limitation, portability and presentation of claims.

- Additional information: Additional and detailed information on Data Protection can be found on our website: Privacy policy