2 de August de 2024

Advantages of low-pressure over high-pressure cleaning

For the cleaning of open surfaces in the food industry (OPC - Open Plant Cleaning), the use of equipment for the application of detergents in the form of foam is widespread. Within this range of equipment, the systems that offer the most advantages are the low-pressure cleaning systems.

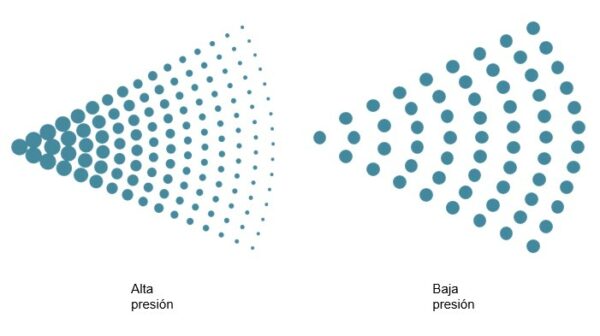

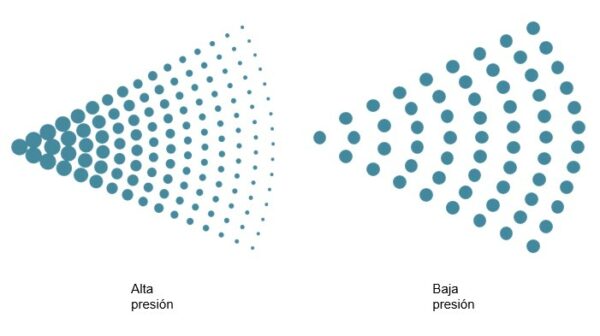

In contrast to high-pressure cleaning equipment, which works at 100-150 bar, systems using water at around 20 bar pressure are called low-pressure systems.

This equipment is designed specifically for application onto surfaces of the four factors needed for correct cleaning as set out in the Sinner diagram.

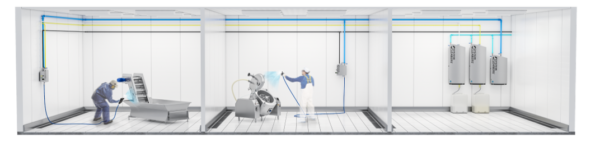

In the example above, the three satellites suck and dilute the chemical individually (decentralised systems), but there are centralised systems that perform the dilution with central units located outside the production rooms, sending the chemical dilution to the point of application at the appropriate dosage:

In the example above, the three satellites suck and dilute the chemical individually (decentralised systems), but there are centralised systems that perform the dilution with central units located outside the production rooms, sending the chemical dilution to the point of application at the appropriate dosage:

OPC cleaning and disinfection processes are normally carried out in 5 stages:

OPC cleaning and disinfection processes are normally carried out in 5 stages:

The higher water flow rate applied to the object/surface significantly reduces the cleaning time, increasing the speed of removal of the deposited residues. Although it may seem contradictory, the effect of the increased flow rate reduces the total water consumption as it yields much more water.

The higher water flow rate applied to the object/surface significantly reduces the cleaning time, increasing the speed of removal of the deposited residues. Although it may seem contradictory, the effect of the increased flow rate reduces the total water consumption as it yields much more water.

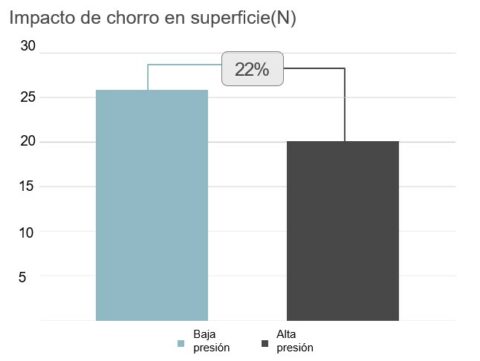

The results show that, when rinsing from 5 different distances, the impact of the water jet on the surface is on average 22% higher than rinsing with high pressure.

A higher impact of the water jet causes the debris to fall off more easily (due to the increased mechanical action), saving time in the cleaning process.

The results show that, when rinsing from 5 different distances, the impact of the water jet on the surface is on average 22% higher than rinsing with high pressure.

A higher impact of the water jet causes the debris to fall off more easily (due to the increased mechanical action), saving time in the cleaning process.

As shown in the graph above, the difference in impact area increases as the distance to the surface increases.

The impact area is of great importance for the maximum efficiency of the cleaning process, as it allows covering a larger area with a shorter time span.

As shown in the graph above, the difference in impact area increases as the distance to the surface increases.

The impact area is of great importance for the maximum efficiency of the cleaning process, as it allows covering a larger area with a shorter time span.

The temperature difference is already significant at application distances of 25 cm, increasing as the distance to the surface increases. At a distance of 60 cm, the difference in temperature drop is up to 13.5 °C.

Temperature is a very important factor in order to achieve the proper fluidisation of grease and thus remove it from the surfaces. A rapid drop in temperature leads to a reduced ability to dissolve grease, thus prolonging the cleaning time and decreasing the efficiency of the process.

Therefore, to improve cleaning efficiency it is important to note that, according to SINTEF tests, low-pressure cleaning systems perform best at distances between 25 cm and 50 cm from the surface.

To achieve this recommended distance, the equipment can be fitted with many types of accessories, such as nozzles with different flow rates and application angles or lances of different lengths.

The temperature difference is already significant at application distances of 25 cm, increasing as the distance to the surface increases. At a distance of 60 cm, the difference in temperature drop is up to 13.5 °C.

Temperature is a very important factor in order to achieve the proper fluidisation of grease and thus remove it from the surfaces. A rapid drop in temperature leads to a reduced ability to dissolve grease, thus prolonging the cleaning time and decreasing the efficiency of the process.

Therefore, to improve cleaning efficiency it is important to note that, according to SINTEF tests, low-pressure cleaning systems perform best at distances between 25 cm and 50 cm from the surface.

To achieve this recommended distance, the equipment can be fitted with many types of accessories, such as nozzles with different flow rates and application angles or lances of different lengths.

With low-pressure cleaning, the droplets formed are larger, falling faster and thus reducing the risk of airborne dispersion and cross-contamination:

With low-pressure cleaning, the droplets formed are larger, falling faster and thus reducing the risk of airborne dispersion and cross-contamination:

- Time

- Temperature

- Chemical action

- Mechanical action

In the example above, the three satellites suck and dilute the chemical individually (decentralised systems), but there are centralised systems that perform the dilution with central units located outside the production rooms, sending the chemical dilution to the point of application at the appropriate dosage:

In the example above, the three satellites suck and dilute the chemical individually (decentralised systems), but there are centralised systems that perform the dilution with central units located outside the production rooms, sending the chemical dilution to the point of application at the appropriate dosage:

OPC cleaning and disinfection processes are normally carried out in 5 stages:

OPC cleaning and disinfection processes are normally carried out in 5 stages:

- Initial rinse

- Application of Detergent (cleaning in foam form, using air)

- Intermediate rinse

- Application of Disinfectant (spray disinfection)

- Final rinse

Characteristics of low-pressure cleaning systems

Increased water flow

Tests carried out by the Norwegian Research Institute SINTEF show that with low-pressure cleaning almost twice as much water flow (exactly 84%) reaches the object/surface to be cleaned compared to high-pressure cleaning: The higher water flow rate applied to the object/surface significantly reduces the cleaning time, increasing the speed of removal of the deposited residues. Although it may seem contradictory, the effect of the increased flow rate reduces the total water consumption as it yields much more water.

The higher water flow rate applied to the object/surface significantly reduces the cleaning time, increasing the speed of removal of the deposited residues. Although it may seem contradictory, the effect of the increased flow rate reduces the total water consumption as it yields much more water.

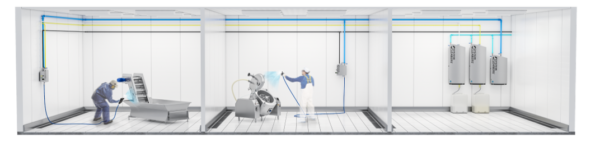

Increased impact of the water jet on the surface

Tests carried out by SINTEF show that, when water is used at low pressure, a greater impact of the jet on the surface is achieved: The results show that, when rinsing from 5 different distances, the impact of the water jet on the surface is on average 22% higher than rinsing with high pressure.

A higher impact of the water jet causes the debris to fall off more easily (due to the increased mechanical action), saving time in the cleaning process.

The results show that, when rinsing from 5 different distances, the impact of the water jet on the surface is on average 22% higher than rinsing with high pressure.

A higher impact of the water jet causes the debris to fall off more easily (due to the increased mechanical action), saving time in the cleaning process.

Larger impact area of the water jet

Tests carried out by SINTEF clearly show that the impact area of the water jet is larger for low-pressure cleaning than for high-pressure cleaning: As shown in the graph above, the difference in impact area increases as the distance to the surface increases.

The impact area is of great importance for the maximum efficiency of the cleaning process, as it allows covering a larger area with a shorter time span.

As shown in the graph above, the difference in impact area increases as the distance to the surface increases.

The impact area is of great importance for the maximum efficiency of the cleaning process, as it allows covering a larger area with a shorter time span.

Better heat transfer: lower temperature drop

Tests carried out by SINTEF also show that, thanks to the higher water flow rate, low-pressure cleaning generates a more efficient transfer of thermal energy from the water onto the surface compared to high-pressure cleaning: The temperature difference is already significant at application distances of 25 cm, increasing as the distance to the surface increases. At a distance of 60 cm, the difference in temperature drop is up to 13.5 °C.

Temperature is a very important factor in order to achieve the proper fluidisation of grease and thus remove it from the surfaces. A rapid drop in temperature leads to a reduced ability to dissolve grease, thus prolonging the cleaning time and decreasing the efficiency of the process.

Therefore, to improve cleaning efficiency it is important to note that, according to SINTEF tests, low-pressure cleaning systems perform best at distances between 25 cm and 50 cm from the surface.

To achieve this recommended distance, the equipment can be fitted with many types of accessories, such as nozzles with different flow rates and application angles or lances of different lengths.

The temperature difference is already significant at application distances of 25 cm, increasing as the distance to the surface increases. At a distance of 60 cm, the difference in temperature drop is up to 13.5 °C.

Temperature is a very important factor in order to achieve the proper fluidisation of grease and thus remove it from the surfaces. A rapid drop in temperature leads to a reduced ability to dissolve grease, thus prolonging the cleaning time and decreasing the efficiency of the process.

Therefore, to improve cleaning efficiency it is important to note that, according to SINTEF tests, low-pressure cleaning systems perform best at distances between 25 cm and 50 cm from the surface.

To achieve this recommended distance, the equipment can be fitted with many types of accessories, such as nozzles with different flow rates and application angles or lances of different lengths.

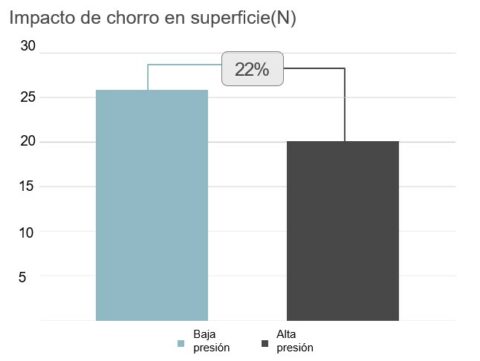

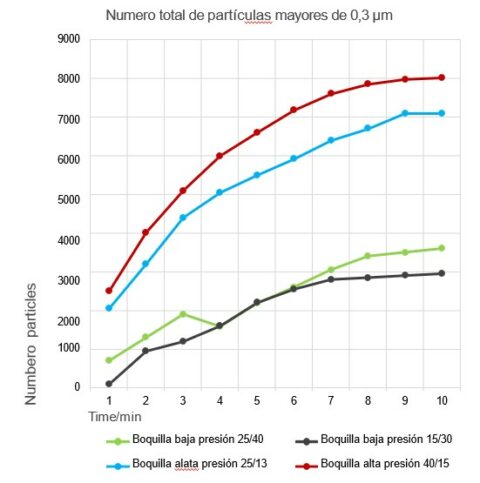

Aerosol reduction

Aerosols can remain in the air for several minutes. Finer droplets are dispersed and may contaminate uncontaminated areas. If the generated aerosols contain and carry microorganisms from contaminated surfaces, they are called bioaerosols. The generation of bioaerosols in the food industry can originate during the production process, but their main formation occurs during the cleaning and disinfection process. Special attention should also be paid to aerosols generated by the spraying of detergents and disinfectants, as these form small droplets that are spread in the air and easily inhaled, increasing the risk of causing respiratory impairment or illness to the personnel applying them. Tests carried out by SINTEF clearly show that cleaning with a low-pressure cleaning unit reduces the total amount of particles in the air by at least 50% compared to high-pressure cleaning:

With low-pressure cleaning, the droplets formed are larger, falling faster and thus reducing the risk of airborne dispersion and cross-contamination:

With low-pressure cleaning, the droplets formed are larger, falling faster and thus reducing the risk of airborne dispersion and cross-contamination:

Employee health and safety.

The cleaning and disinfection procedure using low-pressure systems improves the working conditions of the users compared to high-pressure systems, since:- Less vibration occurs in the hoses

- The noise level is less than 70 dBa

- There is reduced risk of accidental impacts by employees due to hose leaks

Benefits of low-pressure cleaning systems

As a result of the excellent features offered by low-pressure cleaning systems, the following benefits are achieved:- Significant reduction in cleaning time.

- Reduction of water and chemical consumption.

- Better heat transfer: energy saving.

- Less wear and tear on process equipment and surfaces.

- Low maintenance and service requirements.

- Improved working environment: occupational health and safety.

CONCLUSIONS

Open surface cleaning and disinfection systems offer the following advantages over high-pressure systems:- 84% more water flow above the surface

- 22% greater impact of the water jet on the surface

- 39-62% greater water jet impact area (depending on distance to surface).

- increased temperature transmission to the surface.

- Reduction of aerosols

- Reduction of occupational risks: vibrations, noise, impacts, etc.

Do you want more information?

We help you

In accordance with Regulation 2016/679 (GDPR) the basic information on personal data protection is provided below:

- Data controller: PROQUIMIA, S.A.

- Purpose of processing: Managing the sending of information, resolving queries and/or collecting data for possible business relationships.

- Legal Basis: Consent of the person concerned

- Recipients: No data will be transferred to third parties, unless this is legally obliged.

- Rights: Access, rectification, deletion, opposition, limitation, portability and presentation of claims.

- Additional information: Additional and detailed information on Data Protection can be found on our website: Privacy policy